As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Advertising with ‘brewery fresh beer’ is becoming more popular. In a time where the origin of ingredients is more important than ever, every brewery wants to give a feeling of freshness with their beer. To ensure that the customer has the best possible experience, breweries will focus on three factors that influence the freshness (and therefore taste) of their beer.

Oxygen

Even though it is a vital gas for us humans, oxygen is on of beer’s worst nightmare. Oxygen causes beer to oxidize, giving bacteria the chance to convert the alcohol into acetic acid. In general, there are two ways for oxygen to penetrate the beer, before it is poured or deliberately opened in case of a bottle or can. The first way is that oxygen remains in the packaging during filling. The volume of oxygen staying behind is determined by the type of packaging. This is in most cases countered by prefilling or flushing the packaging with CO₂. The migration of oxygen through packaging is best prevented by one-way kegs, bag-in-keg, and bag-in-tank system. These all operate with active oxygen barriers that prevent the oxygen from migrating into the beer.

Light

The influence of light mainly is linked to the character of the hops. The reaction with Ultra-Violet (UV) light can cause hops to react and give a distinctive change to the taste of the beer. To some customers this taste will come across as ‘un-fresh.’ This effect is diminished by using green or brown glass types. However, the best way is to ensure that the beer does not get exposed to light at all. Typical examples on how to do this are cans, Keg Kegs and tank beer systems. In all of these, the beer is never exposed to light on a large scale.

Temperature

Lastly, the temperature control of beer is an important factor to have beer at the ultimate freshness. Fluctuations in temperature can accelerate the aging process and lead to off-flavors. Excessive heat can cause chemical reactions in beer, accelerating oxidation and potentially causing the beer to spoil.

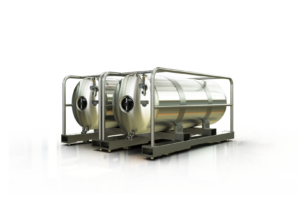

Key is to create circumstances where beer has a constant temperature throughout transport and storage. This can be a challenge with the varying conditions in the steps of the supply chain. Packaging options such as cans, bottles and kegs often experience fluctuations in temperature between production, transport and storage. Virtually the only mode of beer transportation and storage that is controlled during all steps is tank beer

Recent articles

Blog: tankbeer systems for stadiums and concert halls

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: understanding how a tankbeer systems keeps beer at the right temperature

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: Tankbeer transport: finding the right set-up for your unique situation

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: a deep dive into the Pressure Equipment Directive (PED)

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: Using compressed air instead CO2

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: Deconstructing a beer tank and how they work

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: Understanding Duotank Beer Tank Inliners: What They Are and Why They Matter

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: the basics of a tankbeer system

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.

Blog: inner city draught beer delivery

As a brewer, you want to make sure your customers get the optimum experience when they order your beer in a bar.