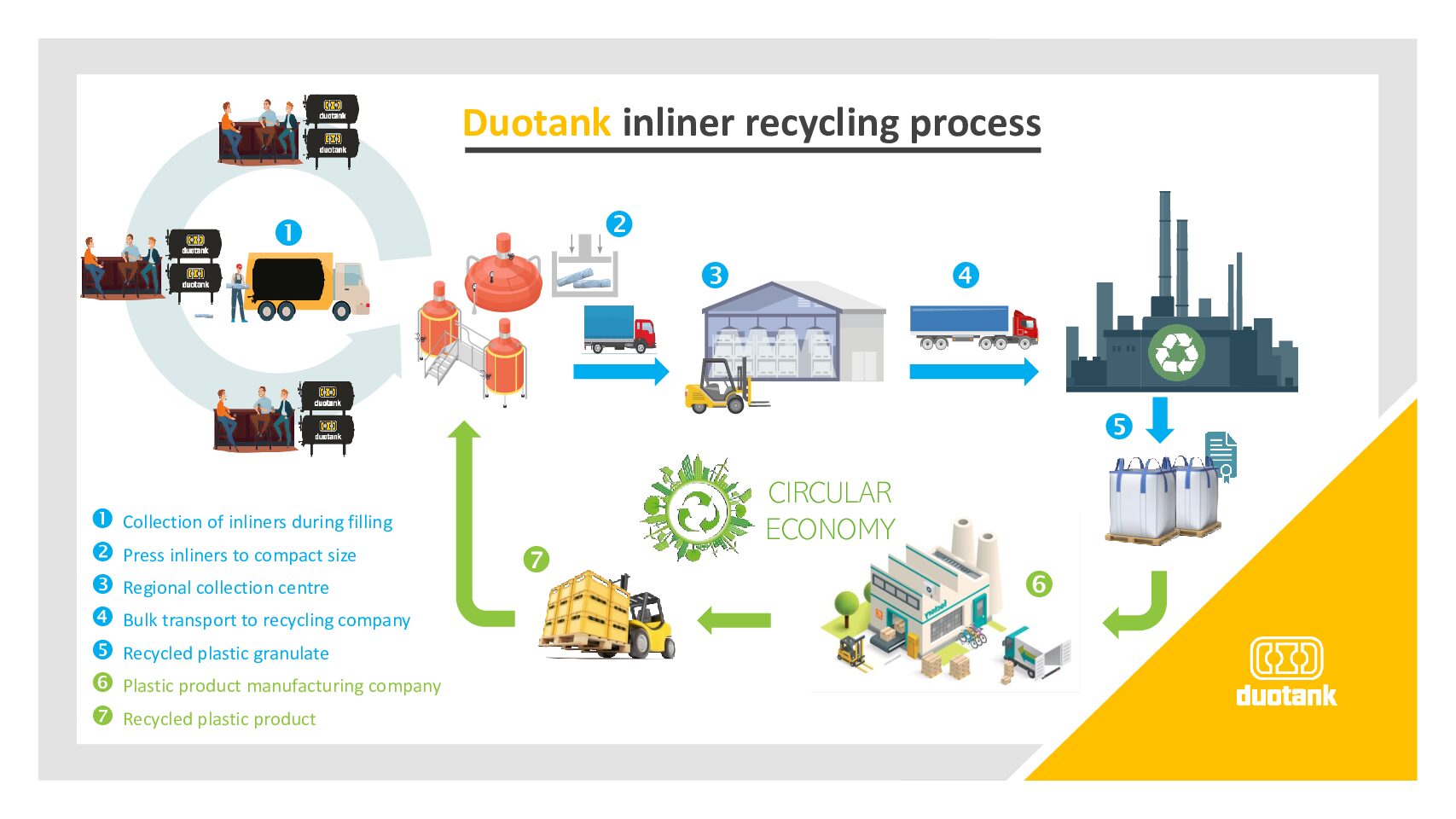

How does it work:

The inliners are collected at the brewery. A press forms the plastic waste into blocks of inliners with an economic size and weight. These blocks can then be collected regionally, which makes transport affordable. Based upon purchase volumes of different inliner types Duotank determines the plastic & residual waste composition and forwards this to the recycler.

Based upon this composition the recycling company combines different batches of inliners (also from other industries) and forwards these to a number of selected recycling factories in Europe. Knowing the exact composition of the supplied plastics the recycling factory can then turn the waste into usable plastic granulate, the base material to produce new plastic products.

The recycling company will issue a certificate stating that the batch of delivered inliners is converted into reusable plastic granulates

In this way Duotank and its partners have made it possible to recycle inliners completely and affordably, enabling breweries to avoid the extra plastic tax.

As a brewery you can even go one step further and specify to the manufacturers of your crates or other plastic products to use a certain percentage of this material making the chain circular and almost cradle to cradle!

For more information about this program, please contact!